gelofish wrote:

gelofish wrote:

This is awesome, got any more updates?

I am coming down the home stretch in getting my 351w build put back together. Everything except the timing cover has been cleaned and painted, all my parts have arrived. I need to:

clean paint timing cover and install seal crank

install the rear crank sleeve

install rear main seal

torque down heads

install and adjust rockers and pushrods

install fuel pump eccentric

install oil pickup

install timing cover

install harmonic balancer

finish sealing engine:

intake

timing cover

water pump

oil pan

valave covers

Install distributor

install flywheel

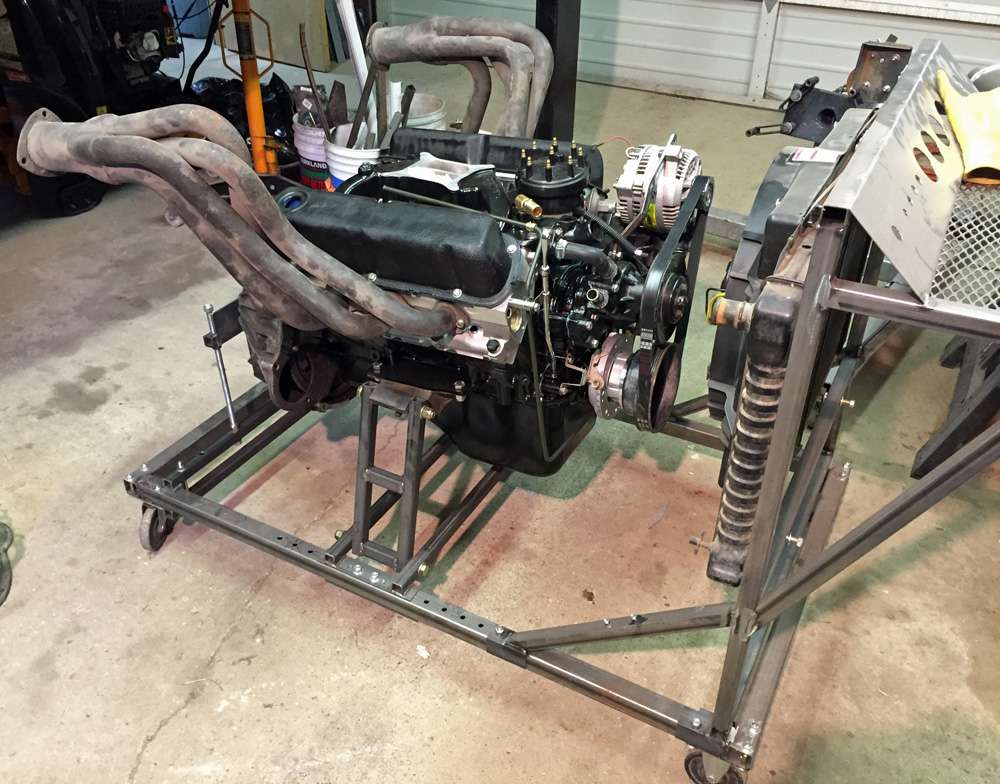

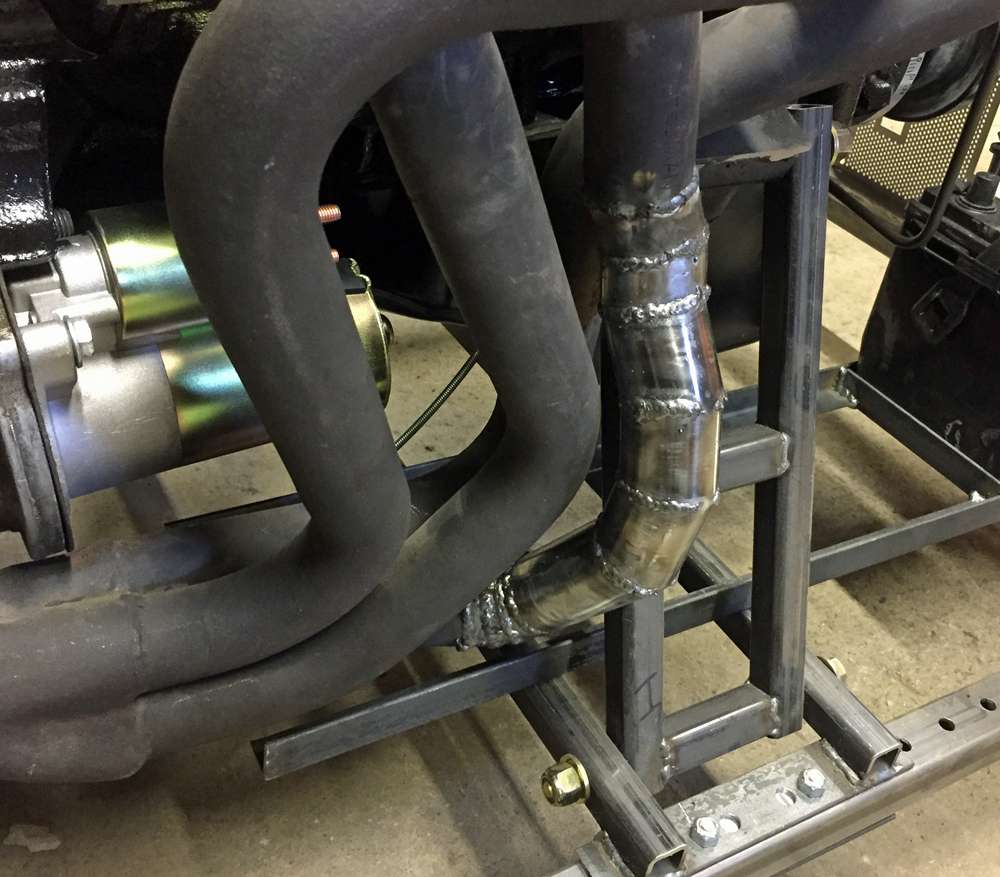

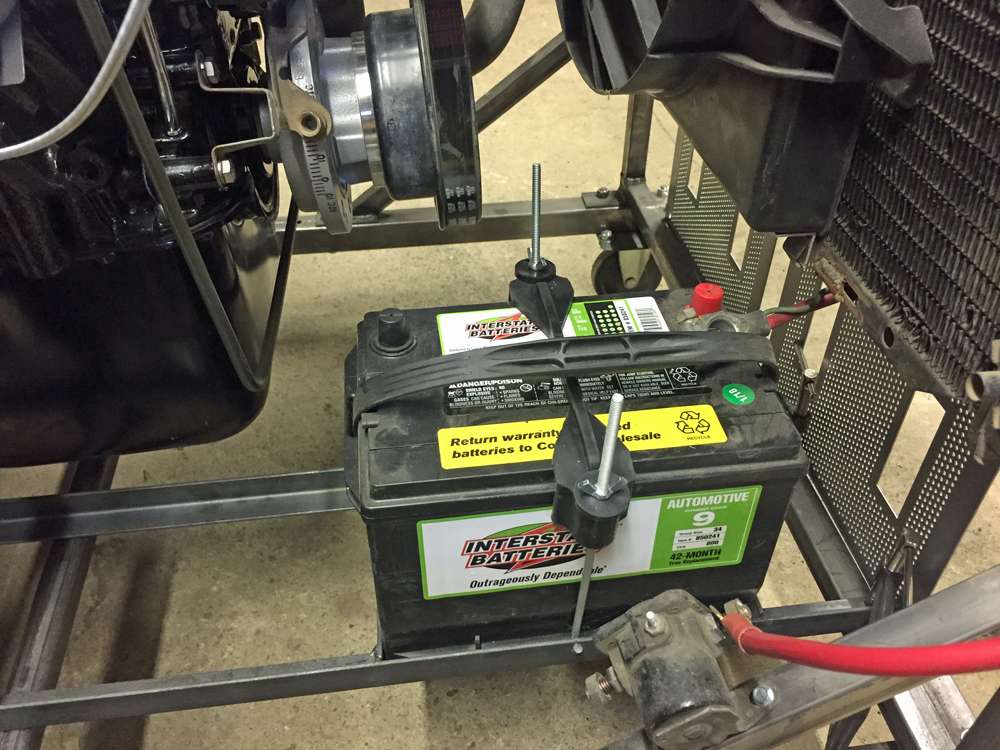

sounds like a lot but it is really one good afternoon other than waiting for the paint on the timing cover to dry. Once I get the engine together I will transfer it to the engine stand and start hooking every thing up and fire it up. Hoping to have some video of a running engine in a few weeks if not sooner.

gelofish wrote:

gelofish wrote: